Tools

Practical Plastics

Most Useful Thing

Thingiverse has a clunky and unreliable indexing system and search engine, to the point that it can be hard to find the same thing twice. So here’s a link to a quick, useful tool: Angle taker for tight spaces.

A while back I made a stab at designing a removable drip tray for the water/ice dispenser on my Samsung fridge, which was inexplicably designed with an oddly-shaped depression that will inevitably become etched by the residue of evaporation. I basically had to take rubbings to get measurements, and my first try got the angled sides wrong.

This little tool captured the angle precisely so I could transfer it to a protractor and correct my OpenSCAD code.

Other Useful Things

Bag Clips

While I generally frown on the idea of spending hours 3d-printing something that can be purchased for pennies at any local store, 2020 and Benito Newsom have made the shopping experience so cumbersome that I’m willing to make a few exceptions. I generally have at least three opened bags of something or other that need to be resealed cleanly, and this set of 3 clips works nicely. There are quite a few remixes and redesigns, but they don’t solve the only problem I’ve had with them a few times, which is the ends lifting off the bed slightly during printing.

It doesn’t hurt them functionally, and it can be avoided by keeping the infill percentage and number of walls down, to reduce shrinkage-induced stress. And we should all reduce shrinkage-induced stress.

2x MicroSD in SD case

When there are once again places to go and things to see, I will take pictures with my cameras. My pocket-sized travel camera fits nicely in this padded pouch, with only the security strap sticking out. The pouch has just enough room for an extra battery and some thin card storage.

Unfortunately, most of the printable MicroSD holders overcompensate for their tinyness by adding substantial bulk. This very simple design is the notable exception, just fitting two of them into a standard SD snap case, of which I have a lifetime supply.

Not a tool…

Apple’s iCloud service crumbled under load on Christmas day, and took 36 hours to recover. The richest company in the world is still struggling to build an online service that can scale.

Remember the days when you could unbox a gift on Christmas morning and it would actually work? Clearly no one at Apple does.

Unrelated

Got Black Ships? Japan has banned foreigners again. Well, at least until the end of January.

Hairspray, baby!

Pete, I’m getting great results with a very thin layer of Aqua Net Unscented Extra Super Hold. More reliable than the glue sticks with much better bottom surface quality. Best applied with a microfiber cloth that’s been wetted with a replacement cap like this one.

PLA (what I’m mostly sticking to right now) adheres very firmly to a heated bed, but pretty much pops off as soon as it cools.

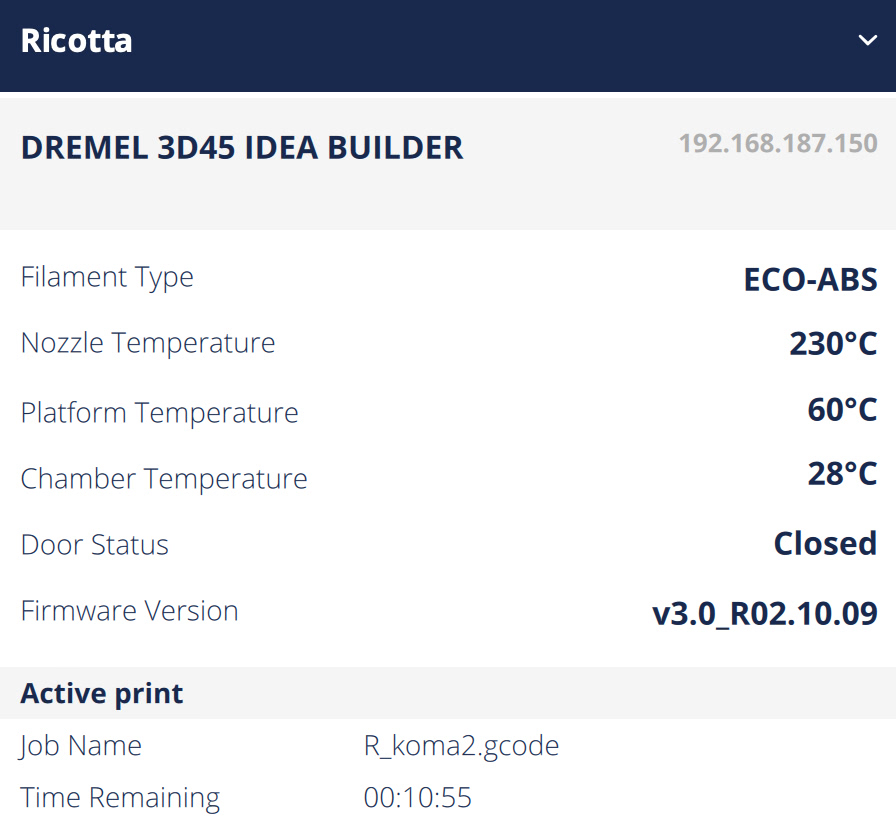

(note on ABS, since I belatedly noticed that’s what you’re printing with)

Unrelated, plastic calipers. 😁

Learn To (g)Code

After successfully printing 6 non-rounded parts with the Hatchbox filament, I told it to print three round ones, namely a ratchet, knob, and sanding jig. All three suffered catastrophic Y-axis layer shifts. So I switched back to what was left on the Dremel-branded spool, re-generated the gcode, and hit go. It worked… better, except for the jig.

It looks very much like the gcode that the Dremel slicer software generates when you try to print a thin-walled cylinder (like the jig) creates a rapid series of XY zigzag moves that causes the Y axis belt to occasionally skip, ruining all the parts currently on the bed. Why it was clearly worse with the Hatchbox filament may be due to irregular tension from my hand-winding, or just dumb luck.

Good thing I already confirmed that I can get good prints with MatterControl, eh? Sure enough, when the same trio of parts is sliced with that app, the printer never makes that distinctive shuddering zigzag noise, and they all come out clean.

I suppose I should take another look at porting the Dremel material and quality profiles to the current version of Cura, as well. Someone claims to have settings for good results with Hatchbox filament, which is worth a shot.

Picture is unrelated and kinda disturbing

3D Kleenex

Disease with no Cura

I experimented a bit with Meshmixer to optimize the orientation and supports for a model before slicing and printing with Dremel’s software. Pro: it was easy to remove the tree-style supports it generated. Con: the surface quality was no better for all the extra work involved, and actually required a bit more sanding to be usable.

So I tried the current version of Cura (which has a bewildering array of tree-support options) with the machine definition copied from Dremel’s older version and the built-in generic filament and quality definitions. The print took just as long as with the Dremel software, but practically crumbled in my hand. All the small parts could be snapped off with very light pressure, and the main body’s 20% infill wasn’t enough to survive squeezing between thumb and forefinger. Definitely need to import the Dremel-specific filament and quality settings before I try that again.

Then I tried to decipher the UI for Autodesk Fusion 360, which honestly looks like it was designed to sell training classes. Also, it has a fairly short list of available machine, material, and quality profiles, so I’d have to enter everything by hand for my printer. Yeah, no. If I can manage to figure out how to use it before the mouse bindings drive me to throw a laptop out a window, I’ll try designing a part and exporting to Dremel’s software. It also really, really wants to keep everything in their cloud, which you have to manage from a real browser; it took me a good five minutes to figure out how to completely delete one accidental upload.

Then I took a brief look at FreeCAD, where instead of having their own UI paradigm, they simply emulate everyone else’s and allow you to pick one. Or more. Initial impression: the 2D tools make Illustrator look like the easiest-to-learn drawing software in the world; I didn’t get to the 3D tools. I did like the Bézier curve visualization, though.

CorelCAD is a full-featured 2D/3D package, and for $700 it ought to be. In prehistoric times I found CorelDRAW a lot easier to learn than Illustrator and used it a lot, but then they had a very, very buggy major release that drove me away, and I never looked back. They have free trials of all their software, and a subscription model for some of them, but the very first question on their FAQ page is:

’nuf said.

Video killed by radio star

The Dremel’s camera went offline during one of my prints, and since nothing was listening on the port, obviously the software had crashed on the printer. There’s nothing checking for this and restarting it, so the only way to get the feed back is to power-cycle, which had to wait until I was done sending test prints for the day. The printer still printed, and the status API kept reporting correctly, so it was no big deal. Their app doesn’t really know what to do when there’s no video feed, but it still functions.

By the way, extracting the Busybox image from the latest firmware

update and running strings on the binaries revealed a few additional

commands in the API: GETJOBSTATUS, CANCEL, PAUSE, RESUME, NOZZLEHEAT,

PLATEHEAT, STOPNOZZLEHEAT, STOPPLATEHEAT; I have no need to try most

of those out. A quick tcpdump while I was driving it from the GUI

showed the two-part command to print across the network: you upload

the file by POSTing to /print_file_uploads with name, filename, and

data fields, then POST PRINT=filename to /command (and then spam

it with GETPRINTERSTATUS every few seconds, at least if you’re

Dremel’s software).

Update: unofficial official GCODE/API manual

So, if I ever get another slicer that generates good code for this device, I won’t have to walk the gcode over to the printer on a thumb drive, through the snow, uphill both ways. That will matter more once I move it upstairs into my office, because while it’s not loud, it is audible, and there doesn’t seem to be a way to turn off the built-in lighting. Closing the office door will make lengthy overnight prints less intrusive.

…unless I ever have a houseguest again, because the guest bedroom is right next to the office.

…unless the guest is my sister, who stubbornly insists that my couch provides a much better sleeping experience. Honestly, if I ever win the lottery and build my dream house, her room will just have a sectional sofa, large-screen TV, and a bookshelf. And excellent wifi coverage. Maybe its own kitchen. Oh, what the hell, just make it a studio apartment without a bed.

Little Monsters

If it ever becomes possible to play tabletop games in person again, mz4250’s extremely large set of free miniatures will be useful. The detailing on some of them is nice enough to scale up for decoration, and it’s not just the complete set of D&D monsters and an ever-increasing set of module-specific characters. There are other genres, as well as disturbing nightmare creations.

No Magic Bullet

I think I’ve gone down enough software rat-holes for now. Back to just coding up shapes in OpenSCAD and printing them with the supplied software and its “old-fashioned” support structures.

Additivity: Dremel 3D45 preliminary review

A few quick comments on my new Dremel 3D45:

-

The documentation is laughably terrible, even supplemented by the online support pages and videos. Between the two, you can manage to get it up and running correctly, but everything was very clearly done by tech writers for a power-tool manufacturer, not by a consumer-electronics company.

-

Why, yes, I did manage to misfeed my filament the first time, resulting in a small test print that looked like it came out of one of the first low-budget 3d-printer kits on the market. Fortunately I knew what a skipping stepper motor sounded like, and was able to quickly abort the print and start over.

-

The touchscreen is kinda cheap for a $2,000 printer. Clear and bright, but only responsive to slow, firm touches. Entering my 52-character wifi password (three times) was quite painful.

-

And, yes, I had to set up wifi even though I had an ethernet cable plugged in when it booted the first time.

-

By the way, all the documentation insists that there is no LAN printing support, and that if you want to print without a USB cable or thumb-drive and watch your job through the built-in camera, you must connect to their cloud. Neither of these statements is true. Works great, auto-detects printers on the local LAN (wired or wireless), shows the progress and remaining time, and the camera even includes the filament spool in the frame so you can visually confirm that you’re not running low.

-

Also, their cloud setup got stuck in an endless SSO-auth loop. Yeah, fuck the cloud.

-

The bundled software, which initially seems a bit limited, is in fact quite competitive, being built around the open-source Cura package, which means that it includes the ability to read

.fdm_materialfiles for a wide variety of third-party filaments. -

Dremel also supports and recommends Simplify3D, which is well-regarded despite its complete lack of anything resembling a material library. It has a basic profile for the Dremel models, but doesn’t even support the material that comes in the box.

-

That is, Dremel officially sells and supports branded PLA, PETG, Nylon, and Eco-ABS (actually a modified PLA with a confusing name), and ships the printer with one spool of Eco-ABS and one of PETG. Simplify3D’s device profile lists PLA, ABS (apparently Eco-ABS), and Nylon; they don’t include PETG in any of their profiles, and do not clearly document how to add additional materials, although they have web pages describing common parameter ranges for many generic types of filament.

-

One last note on software: Simplify3D requires an active Internet connection at all times to work, and their “free trial” involves giving them $150 up front and asking for a refund within two weeks. Yeah, fuck that.

-

Note that third-party filament, while supported, has to be rewound onto a Dremel-sized spool before use, and you’ll want to remove the RFID tag so the printer doesn’t auto-detect it as the wrong stuff. There are plenty of designs on Thingiverse for assisting with this process.

-

By the way, Dremel says they’ll send me two free rolls of filament for blogging a review of my printer. “Your proposal is acceptable. Especially since I was going to do that anyway.”

-

Update! Just noticed that Dremel’s software also auto-detects thumb-drives as a destination to save your gcode, and offers an eject button after the copy finishes. That’s convenient.

Network printing

Why, yes, I did name it Ricotta; she’s a pro maker, dawg. Er, “pro maker dog”.

The proof is in the solidified pudding

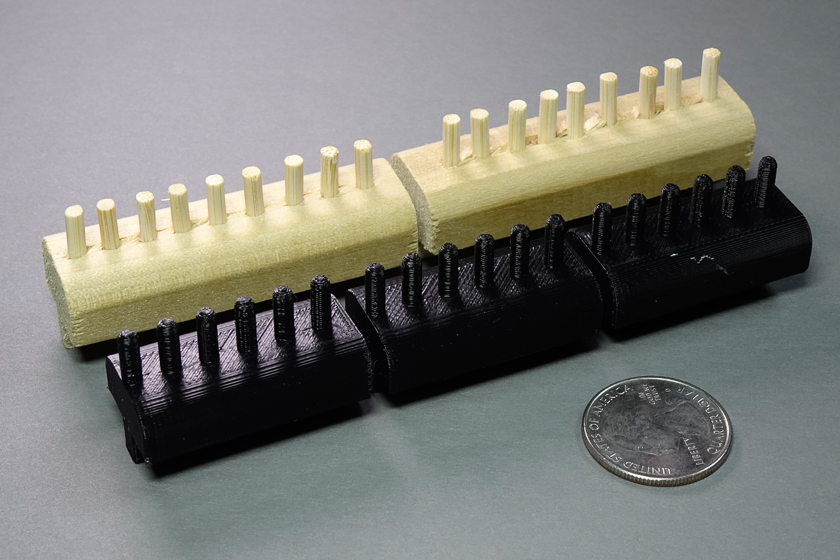

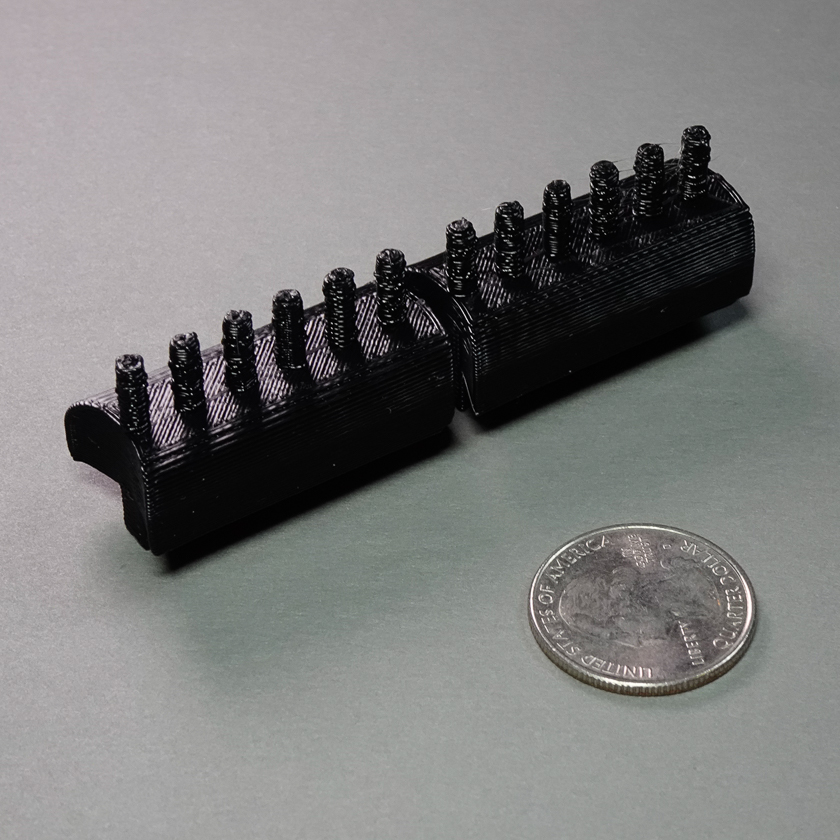

My first print job was a redesigned koma for the baby takadai. 30 minutes at medium quality, 30 more minutes after I broke one of the pins off while remembering how to cleanly remove the supports (been a few years since I used one of these, and the documentation consists only of the words “use needle nose pliers”), and I had a part that fit perfectly and worked exactly as intended.

I had it print 9 more overnight, and woke up to a full set of koma much better than what that poor woodworker had managed with a router, a drill press, and not nearly enough time to get them all out the door in time for the conference.

Note that the 3d-printed design does something that would have been a real pain with a drill press: the front pin is exactly at the front, so there’s no double-width gap between pins on adjacent koma. I swiped the idea from the Braidershand design, which gets very close to the front of the koma with their pins. Little touches like that are why their gear has an 18-month waiting list.

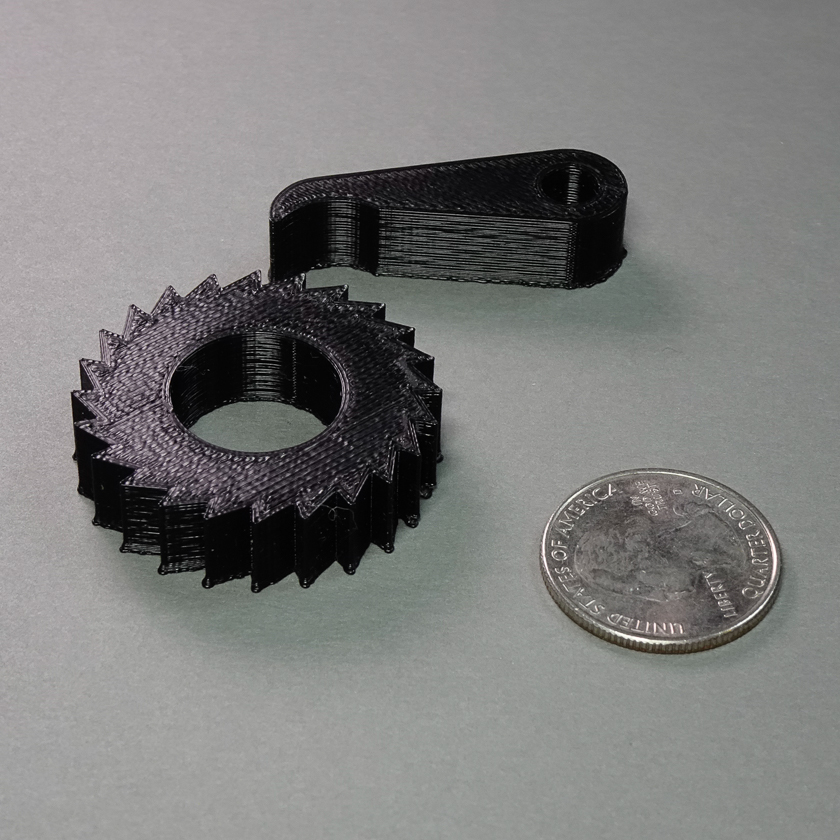

Second job was a gravity ratchet and pawl downloaded directly from the McMaster-Carr online catalog. I’m going to scale and recreate this design in OpenSCAD to use for the take-up reel in my next babydai mod.

Keep Calm and SOHCAHTOA

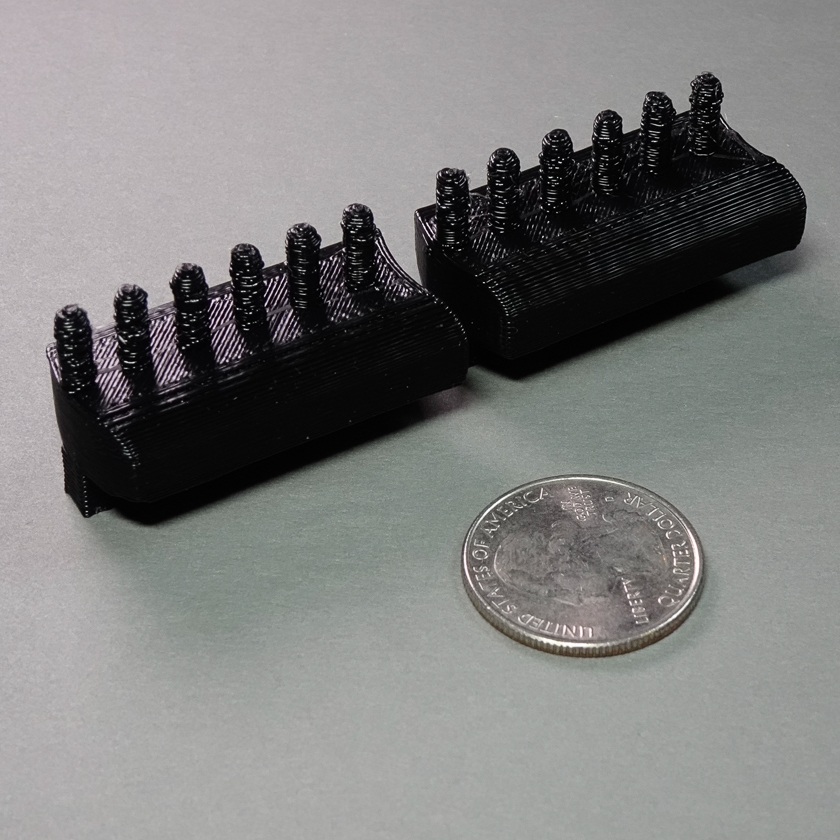

For the third job, I had a sudden inspiration about how to solve the problem of tensioned threads falling into the narrow gap between two koma: curve the ends. This took longer to work out on paper and in OpenSCAD than it took to print in high-speed draft mode (30 minutes for two).

They came out exactly how I expected, and I was quickly able to confirm that the idea was sound, but I really wanted the curved ends to go the other way…

Thirty minutes later, I had another pair of prototypes.

24-hour opinion?

At this point, I have full confidence that the Dremel 3D45 will reliably deliver excellent 3D prints with their branded filament, and that I should be able to successfully import working settings for common third-party filaments when I get around to buying some.

The hardware is solid and well-designed, the software is quite capable, the filament seems to be of decent quality (if a bit hard to find right now, between Corona-chan and their change from 500-gram spools to 750-gram), and the price is reasonable for the feature set. The packaging is excellent, by the way, and easy to reuse for travel or repair.

I haven’t used the High or Ultra quality settings yet, or increased the infill percentage; Medium/20% was smooth enough and strong enough for koma with 1/8-inch pins and small weighted tama. High-Speed (draft) is kind of ugly and a bit stringy, but does what it’s supposed to.

“The battle’s done, and we kinda won…”

My next project will be a more significant drop-in mod to the baby takadai, relocating the torii, take-up reel, and sword pads, unlocking the ability to use all those new koma I printed and make much wider braids with up to 48 weighted bobbins. I’ll be releasing the OpenSCAD models and STL files so that any of the other conference attendees can mod theirs. Given the crowd, though, I’ll likely also end up printing a few sets to send people. 😁

After that, well, as much as I love the capacity of the 22 9-pin koma on my Braidershand takadai, I also like to braid with thick yarn, and my first attempt at that made me wish I had a set of 6-pin koma with big wide gaps between pins. And since my OpenSCAD design is parametric, that’s just a few long print jobs (roughly 5 hours and 38 grams of filament, each). Hardly a project at all. I’ll probably do them in white; black would be pretty harsh against maple.

Then there’s that complete parametric takadai design I did a few years back, which could be easily framed with connectors like Jonction P. And the long list of CNC projects I still haven’t gotten to. And this idea I just had for an easy tilt/shift adapter for my Sony a6500 and an old Mamiya 6x6 lens. And…

No boxes

I briefly toyed with the idea of designing parametric boxes for tama storage, since I have large quantities of bobbins in different sizes, weights, and shapes (236 total at the moment, but there will be more someday). Then I went to Michaels, based on a tip from the recent kumihimo conference. Their 99-cent crayon boxes hold 4 standard-size tama, their $1.99 pencil boxes hold 10, a larger pencil/craft box holds 9 large tama, and somewhere else in the store I found boxes that were perfect for holding 16 of the latest thing in affordable tama (another conference tip).

I don’t think I’ll need any more tama or boxes this year, but there will come a day when I’ve got 60 of one weight on the big takadai, 39 little ones on the babydai, 32 on the big marudai, 9 on the little marudai, and three dozen cats to feed.

Corona-chan Wants Candy

Unrelated, this is the first time in 20 years that I have had zero trick-or-treaters, down from the usual ~120. I bought a few pounds of candy just in case, but especially since I’ll be working from home until June, I didn’t risk a big buy.

This just in:

Fans spinning up on your Mac laptop during high network traffic? Apple ships a user-mode driver for common USB-C and Thunderbolt docks.

Thanko: USB-powered UV Mask Sanitizer

Part of their things-you-might-need-right-now page, which also includes a mask washer, a “personal air cleaner” torc that wouldn’t do jack against viruses, a desk fan that would just spread viruses, and their famous full-face pollen shield, which at least has the virtue of keeping you from touching yourself.

Helpful list for Pete...

Since his wife has polluted his search history with Japanese sewing terms, here are some more:

- アクリル acrylic

- アサ/麻 hemp (ヘンプ) or linen (リネン)

- ウール/羊毛 wool

- カシミヤ cashmere

- カツラギ katsuragi (thick cotton but lighter than denim)

- ガーゼ gauze

- ギンガム gingham

- ギンガムチェック gingham check

- クレープ crepe

- コーデュロイcorduroy

- サテン satin

- シャンタン shantung

- シャンブレー chambray

- シルク silk

- シーティング sheeting

- ジャカード jacquard

- スウェッド suede

- ソフトデニム soft denim

- タフタ tafetta

- ダブルガーゼ double gauze

- チノクロス chino cloth

- チュール tulle

- フラノ flannel

- ブロード broadcloth

- ボイル voile

- リネン linen

- レース lace

- レーヨン rayon

- ローン lawn

- ワッフル waffle

- 厚手デニム thick denim

- 帆布 canvas

- 持ち手テープ acrylic tape for bag handles

- 綿, コットン cotton

I haven’t been in the fabric district in Tokyo, but we did spend a merry hour in Nomura Tailor in Kyoto buying tablecloth fabric for our mom.

Sweat the little stuff...

These are absolutely brilliant, and I’ve never seen them in the bath/plumbing department of any store:

A set came with my Toto Washlet adapter kit, and after realizing how they worked, I will never again buy a toilet lid that comes with the standard craptastic auto-loosening bolts. As a bonus, Toto lids come with little rubber strips that further improve their side-to-side stability.

In other Amazon news, it looks like they’ve not only fully restored the recommendation tiles, but ditched the “buy it again” tiles and created a separate page that lists them out individually instead. Since I was quite sick of having to scroll past the things-I-won’t-buy-again, I’m a big fan of this change. The new buy-it-again page also seems to sort actual repeatable items to the top more reliably, although it still thinks that I go through an awful lot of Loctite, and that laptop stands are a consumable item.

And at the bottom of the page, it still claims that “Recommended items other customers often buy again” includes things like the Bluray collection of “How not to Summon a Demon Lord”…

Update

Sigh, no, the buy-it-again garbage tiles are back. Must have been briefly turned off by the same sort of glitch that took out the recommendations over the holidays. Oh, well.