Tools

Thicc Cam

Sticktoitivity

Accepted wisdom is that the maximum practical layer height for a given nozzle size is ~80% of its diameter, or 0.32mm for the common 0.4mm nozzles. I was tinkering with Cura’s adaptive layer height feature (which does not offer the customizability of PrusaSlicer’s, and is hidden away as an experimental feature), and it happened to generate some layers all the way up at 0.4. So I figured, what the hell, let’s try it on something that doesn’t have to be sturdy, and that would still work just fine if the top half fell off. Or even the top 2/3.

Turned out just fine, with some very light stringing on the inside of the tube that was easy to shave. Fits nicely, too. I’m sure there are plenty of models where 0.4mm layers wouldn’t work, but it’s a time-saver when it does.

(and, yes, if I want to really speed things up, MicroSwiss does make 0.6mm and 0.8mm nozzles for the 3D45, as well as replacement 0.4mm ones; all of them are also rated for abrasive filaments, something I’ve had no reason to try yet)

Related,

My miter box cam pin has finally been indexed on Thingiverse, and shows up both in searches and in my profile. It took two months.

Found a Zorkmid

Well, printed one, anyway, as a Cura test. Came out pretty decent, printed on edge on a raft.

Dremelizing Cura

Someone has work-in-progress configs on Github to get the current version of Cura to work with the Dremel 3D45. The basic functionality is there, but there’s no network or camera support, and the output quality is… poor (way too much retraction and stringing, and big gaps in pin-like elements). I’m happy with PrusaSlicer for now, but it’s nice to see someone working on more options.

Incidentally, I took a look at how Dremel got the network printing and webcam support into their customized old version of Cura. They heavily edited the UltiMaker 3 script to use their API, but it looks like they never got any kind of network discovery working. It would be faster to write a new Python plugin than to try to modify the current version of the UM3 code, especially since I’ve already got a working Bash script.

Quality update!

To no surprise, replacing the 6.5mm retraction with the 2-3mm that Dremel had in their version of Cura significantly improved the results. I can now do head-to-head comparisons between Cura 4.8 and PrusaSlicer 2.3, to decide which one handles specific parts better.

For my babydai koma, I find the overhang+supports quality unacceptable in both, so I’ve added some 0.5mm-wide manual supports to the model that can be easily snapped off. This forces both slicers to treat them as bridges, which significantly improves the results. And cuts the print time and filament use a bit.

Stop, Drop, and Spool

I ran out to Costco in between meetings Friday, where I found Clorox sanitizing wipes for the first time since March. A 5-pack of giant containers, of course, Costco being Costco, and it turned out that two of them had been crushed just enough that they’d be dried out by the time I wanted them, so I pulled out the wipes and double-bagged them in freezer bags.

Before I left, I started a six-hour print job. When I came back, it was finished. Or, more precisely, it wasn’t printing any more, and there was no error message on the display, but it was only maybe a third done. It looked fine, I had plenty of filament left, and a quick extruder test showed no issues of any kind. I wish I’d left my status script running, which would have captured any error messages.

Lesson learned. Reprinted the same file and it worked perfectly, of course.

The Off-By-8% Solution

I couldn’t understand why my print-in-place hinges were failing. They worked perfectly in the Squeaky Sunlu PETG, but they were so fused together with the Hatchbox PLA that trying to break them free broke the model instead.

Then I discovered that I’d somehow set the extrusion multiplier to 1.05 for that filament, when the correct (calculated and verified) value was 0.97. Oops.

ObAmazon:

Purge Nozzles, Not People

If you want to print stackable boxes…

…this is a well-designed set, with free samplers. The only real limitation (besides the time and cost of 3d-printing boxes in the first place) is that stacking only works one way. For instance, you can stack 3 1x1 boxes/lids on a 3x1, but not the other way around. They’ll be almost stable, but not quite.

I’m going to reverse-engineer the design into a parametric OpenSCAD program. Not to undermine his sales, but to alter the basic layout (multiples of 60mm X/Y and 20mm Z) to better suit my needs. If I ever get to drive to a kumihimo conference again, I could do with some better organization for supplies. The incredibly cheap stackable pencil and crayon boxes at Michaels were the sensible choice for my large collection of tama of different weights and sizes, but there’s a bunch of fussy little stuff that still ends up in ziploc baggies and makeshift toolboxes.

I could also do something like the box inserts people are creating for board games (one of the refreshing non-printer-parts categories of object being posted), but I like the flexibility of the grid design.

+1 Bed Of Adhesion

The Dremel 3D45 has a removable glass print bed. I have two of them, so I can pull out a finished print and immediately start another one, allowing the first bed to cool and release the print.

Occasionally, objects with large flat bottom surfaces show a diagonal wave pattern that indicates the nozzle is too close to the bed, something I thought I’d sorted out weeks ago. It wasn’t until I tried printing various samples from the above box set back-to-back on freshly-cleaned beds that I caught on: my two beds have slightly different heights. I’ve now labeled the one that requires an extra +0.1mm Z offset.

(I really miss the tool-height sensor on my Nomad CNC; a lot of 3D printers have automatic bed-leveling systems, but you pretty much have to go to industrial models to get one that can verify the exact Z position of the nozzle tip(s))

Microfiber and a binder clip

I went with the simplest filament filter and loaded up the Sunlu PETG again. Much better, with only the expected minor defects of a filament I haven’t gotten the parameters quite right for. The only poor result came from printing something large enough that the skirt ran all the way to the edge of the bed, and lost adhesion in a few small spots. It didn’t harm the print at all, since the head never even passed over the skirt once it got the first layer down. Either I didn’t have enough hairspray at the edge of the bed, or it was just enough cooler at the edge to pull up the corners a bit; both are fixable, since I was at the low end of the temperature range and I have lots of hairspray.

"There's a click before the squeak"

After several quite successful prints with the Sunlu PETG, I started getting occasional defects on the vertical edges, accompanied by squeaking or clicking noises. After some basic troubleshooting and a few hits of the “purge” button, I watched the next print lay down a perfect first layer followed by a big glob of filament that stuck up high enough for the nozzle to plow right through it and create a loop.

I switched back to the Hatchbox PLA and kicked off a 5-hour print, and had no defects or unusual noises. I’ll have to inspect the Sunlu filament carefully; with luck it’s just surface cruft that can be removed with a filament filter.

…as soon as I find a filter design that is A) sensibly printable, B) doesn’t cause immense drag on the filament, and C) doesn’t occasionally shed foam onto the “cleaned” filament. Most promising idea I’ve seen so far is to double-fold a small piece of microfiber cloth and attach it around the filament with a standard binder clip.

(and, no, I won’t use it to “oil the filament”; that seemed like a bad idea even before I read up on it)

In other news, my two free spools of Dremel PLA arrived, and instead of the old half-kilo spools I was expecting, they’re the new 3/4-kilo size. Both blue.

Universal spool adapter

Thingiverse is in a horribly broken state, and apparently has been for quite a while (1, 2, 3, 4, 5). The Customizer feature has been down for months, and the search engine still hasn’t registered the miter box cam pin I uploaded over a month ago. Despite being downloadable from the direct link, it doesn’t even show up on my profile page.

(a lot of people seem to be migrating to Cults3D, which is at least functional, although the ongoing infestation of garbage seems to be clobbering its performance; I mean, how many dozens of kit-bashed buddha-with-another-head variations does anyone really need to upload in one day? Also, you have to create an account before they’ll let you download anything, and they don’t have an equivalent to Thingy’s customizer at all)

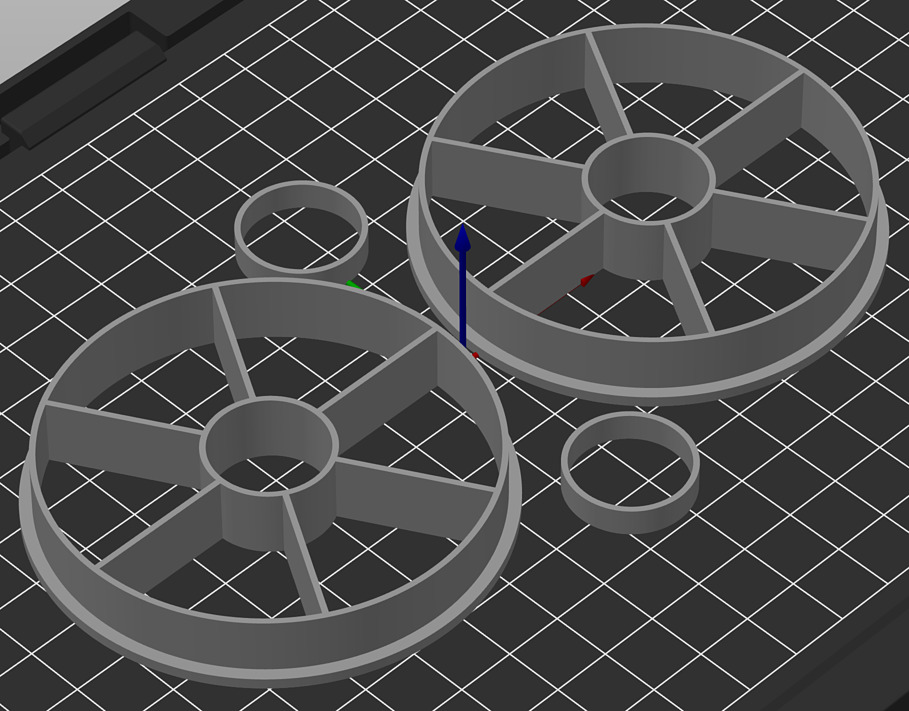

So I haven’t bothered to upload the customizable spool adapter I made to fit Sunlu filament to the Dremel 3D45 external spool holder.

Printed at 0.3mm layer height, all four pieces only use up 17 grams of filament, and take less than 90 minutes to print. OpenSCAD source after the jump.

Playing With Your Spool

The external spool holder works well, although it’s a tight fit on the 3D45’s built-in spool-holder cylinder. The creator originally designed it for a 3D40, which has a slightly different diameter, and apparently used someone’s measurements for the 3D45 without personally trying it. I opened it up a bit with some sandpaper wrapped around a dowel, and it went into place without force.

Does it work? Yes; I anticipate no issues with reliable handling of third-party (and most Dremel) filament. The only obvious difference is that the open side reduces the chamber temperature by ~5°C. My makeshift dust cover, a 12-quart square Cambro propped up on its side over the spool and opening, cut that to ~1°. Instead of building a dust cover, I might just end up making a better stand for the Cambro and put a small tray of dessicant inside to keep the filament dry.

Fun Dremel firmware fact: if you print the same filename twice in a row with different contents, the printer will remember the total time of the first one, and report bogus completion percentages for the second one on the display and the API.

Having used up most of the purple PLA, I switched to the roll of translucent PETG that came with the printer. This had to go inside, because despite being one of the new 0.75 KG spools, it has a slightly smaller hole. Since this is my first time working with PETG, and I’m using PrusaSlicer’s generic profile modified with Dremel’s temperature settings, I started small, printing a known design that didn’t require supports.

It worked perfectly, and gyroid infill looks pretty cool showing through the translucent surface. Not an effect I’d always want, but it can add some visual interest to an otherwise boring object. The second print (one of the ubiquitous “thumb book holder” designs) at first looked like it had adhesion issues, until I re-checked the model and found that the long, thin ends of the arms were curved up so they didn’t touch the bed.

I’ve got a few kilos of colored PETG coming tomorrow, so I think I’ll save the rest of this one for things that would benefit from the frosted appearance, and switch back to PLA for today; I promised to make a batch of babydai koma for someone.

File under ‘baffling’…

In one of my recent Amazon orders, I included a 3-pack of Aqua-Net unscented super extra hold hairspray, since it’s been working out so well for print adhesion. Amazon reports that it shipped yesterday FedEX Ground from the vendor “challways”, and will arrive sometime after January 8th. A 4-pack arrived today via OnTrac in a walmart.com box with a jet.com return address on the shipping label. It’s the right stuff, though, so I’m kind of wondering if more will show up. The 3-pack was already going to be enough to last me a very long time, so I hope not.

Below, Mamako solves an adhesion problem…

In other news…

Valentine’s Day store displays are going up already.